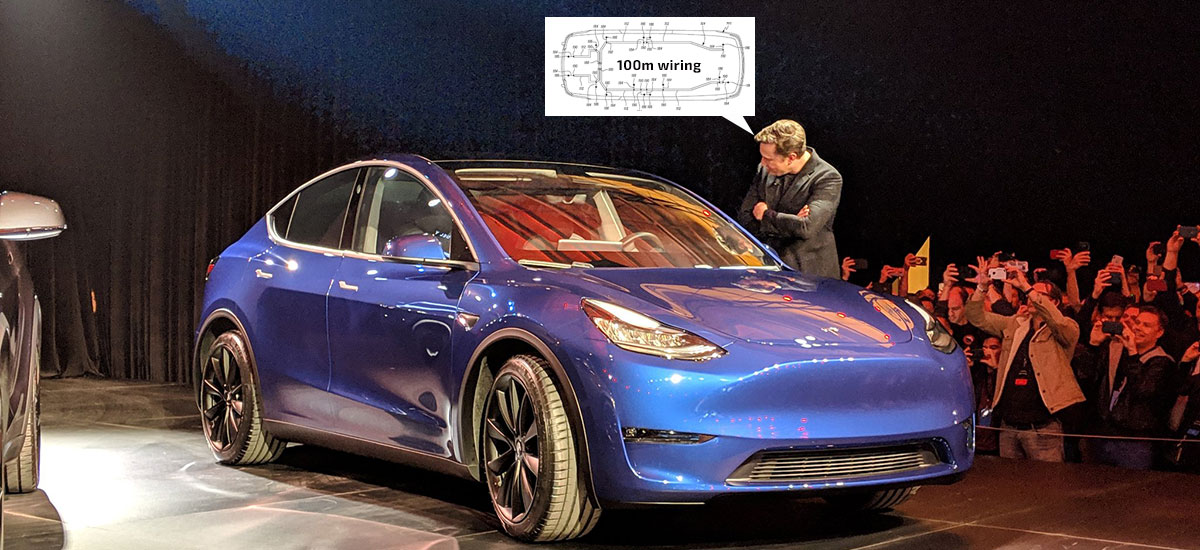

Tesla’s revolutionary wiring system architecture invention gets patented for Model Y and beyond

Telsa recently obtained a new patent for a wiring system architecture which is ‘revolutionary’ for the automotive industry as it aims to excessively reduce the length of the entire wiring used in manufacturing an electric vehicle (full patent PDF and illustrations below).

Since Tesla Model S has 3 kilometers of wiring harnesses which Tesla was able to reduce to 1.5 kilometers while engineering the Model 3 now the Silicon Valley-based automaker wants to take it to next level, to bring the entire wiring used in their vehicles to be around ~100 meters only.

Tesla Model Y should be the closest vehicle for the implementation of this wiring reduction and enhanced automation invention as it goes to production by fall 2020 but the chances of it being brought to the Tesla Pickup Truck and the Next-gen Roadster shouldn’t be out of the question.

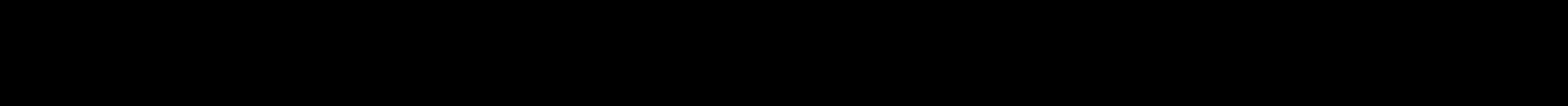

The above illustration of the Tesla Model 3 battery pack penthouse shows how Tesla has tightly integrated various components to reduce the amount of wiring required for the needed operations, with the new patent Tesla is taking this approach even further (read in-depth about Model 3 battery pack in my EVAnnex article).

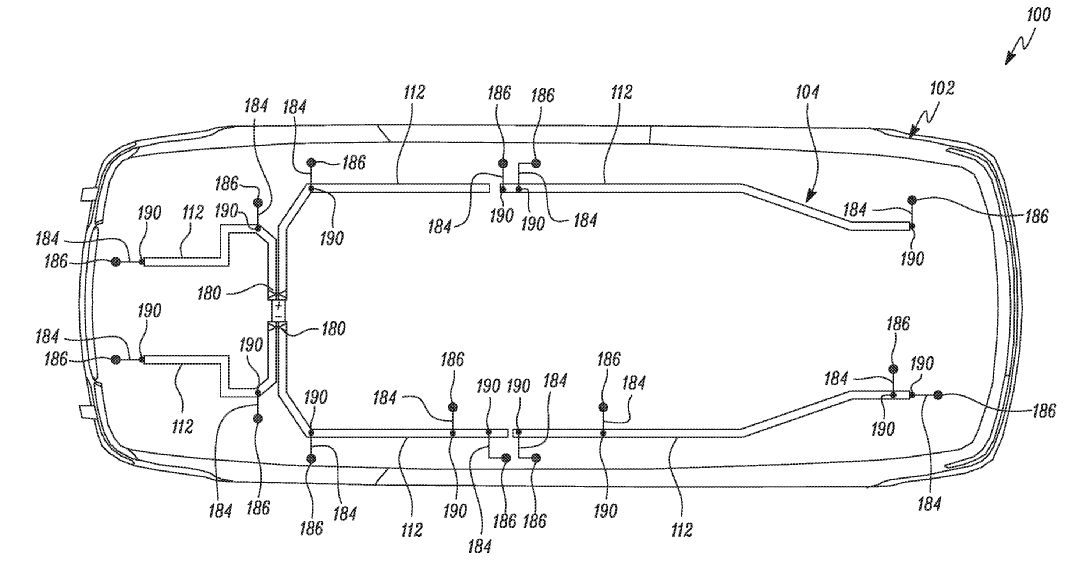

In addition to reducing the length of the wiring needed to connect all the electrical and electronic components together, Tesla with this latest patent is also aiming to use robots in handling the wiring harness connections instead of humans, the ultimate purpose ‘increase the speed of production’.

This patent application (#20190217794) states the purpose of this patent as:

Traditional car wiring for vehicles are piecemeal solutions. Typically, there are different wiring harnesses that connect each different electrical component to a central battery or power source. Each component receives power but requires multiple wiring harnesses for communication and signals. The total length of the wire may be many miles within a single-vehicle. These wiring harnesses typically consist of multiple round conductors that are not rigid. Round conductors are not optimal for transmitting current and the lack of rigidity of traditional wiring harnesses requires assembly into the vehicle using human hands, which can be a slow process. Further, connecting each component to the central battery is not optimized on an automobile level.

The last line above might be an indicator that the 12v battery in Tesla vehicles might get eliminated in future vehicles or future models of the current vehicles. Lowering the need for human hands in the manufacturing process has been a long-time vision of the Tesla CEO Elon Musk.

Tesla’s also recently got the patent approval for a ‘giant unibody casting machine’, that will create the entire car’s frame in one go, together both of these patents seem a giant leap towards Elon Musk’s vision for an Alien Dreadnougt at the Tesla factory.

The entire details of this latest Tesla wiring patent can be seen in the following PDF — let us know your thoughts in the comments section below on how this new invention will revolutionize the entire automotive manufacturing sector.

Follow us on Google News ![]()

Tesla Patent: Next-gen Wiring System Architecture

Tesla Model Y Wiring Patent by Iqtidar Ali on Scribd

Related:

- Tesla production to take a giant leap after obtaining the patent for a ‘Unibody Casting Machine’

- Tesla Semi Design Patent and Nikola’s $2B lawsuit

- Download the entire Tesla Model 3 parts catalog in PDF

- Tesla is NOT the best car I’ve owned, the true story of a Model X owner

- Design patent details of the three Tesla Model 3 wheels

No Comments