Tesla production to take a giant leap after obtaining the patent for a ‘Unibody Casting Machine’

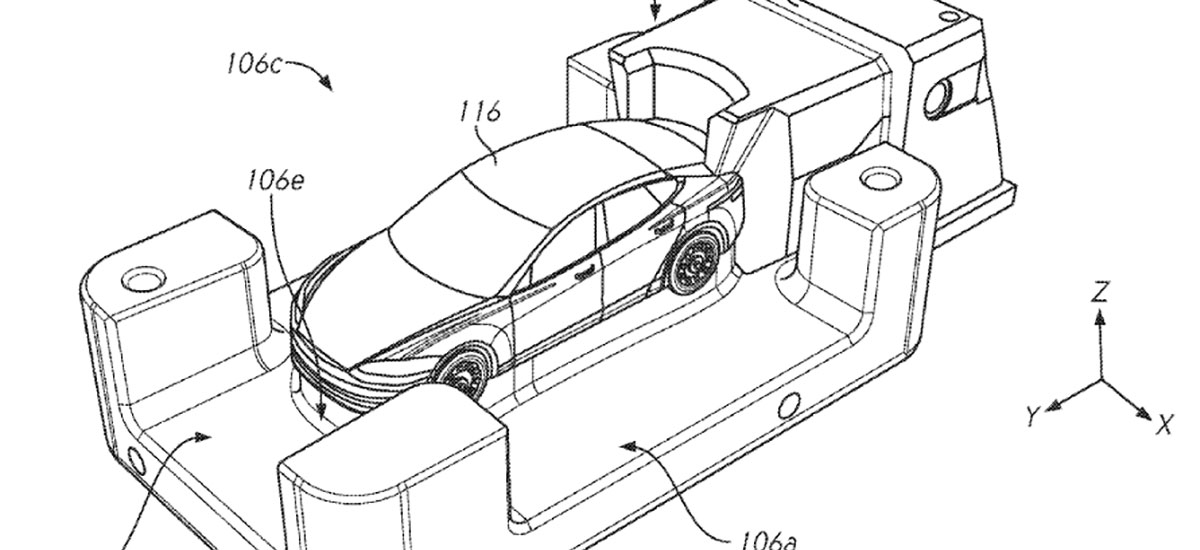

Tesla (TSLA) has wisely and quietly made arrangements to shut up all the critics on its production capabilities once and for all — Tesla Inc. just obtained the patent for a giant machine that will create the entire body frame of a car in a single press, yes it is called the ‘Multi-Directional Unibody Casting Machine’ (patent images and info below).

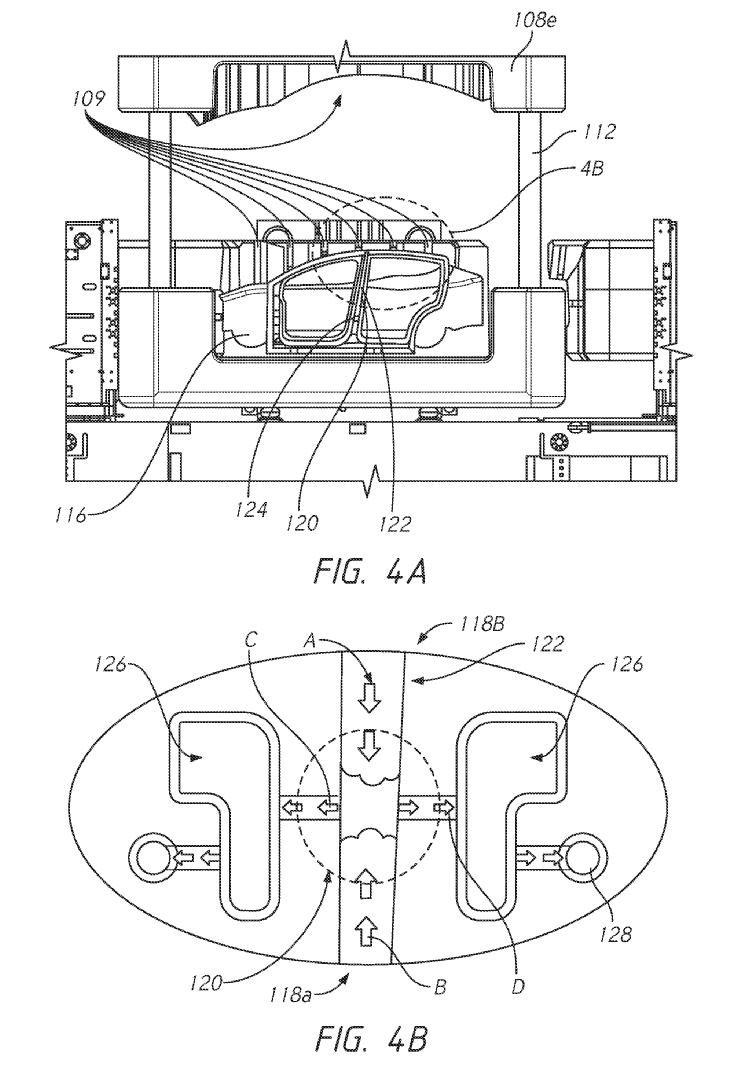

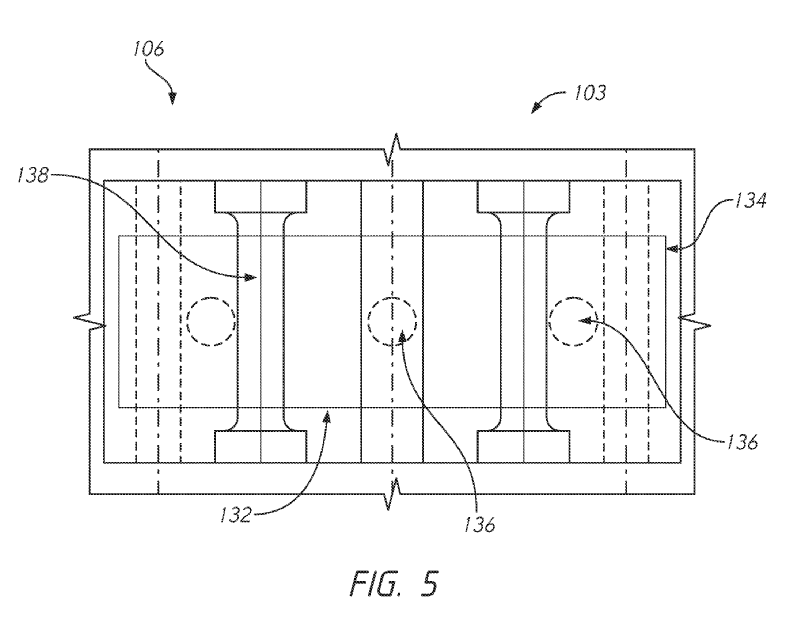

As we can see in the featured photo above and all the patent images below, it is a big big press machine that will produce the car’s body in one go or at least in the minimum amount of time and that will enable Tesla to increase its production numbers manyfold, imagination is the limit.

Tesla applied for this patent last year and has gotten the approval just last week, this is great news for Tesla’s near future as 2020 will mark the beginning of production start for the Next-gen Roadster, Tesla Semi, and Model Y. Although looking at the patent files it’s unclear which car from the existing or upcoming Tesla lineup will first be built using this giant casting machine.

The inventor of this machine mentioned on the patent document is Matthew Kenneth Kallas who seems to be a Tesla engineer but we are not able to fetch much information on his professional profile yet.

The abstract/summary of the patent application states the following (full patent PDF below):

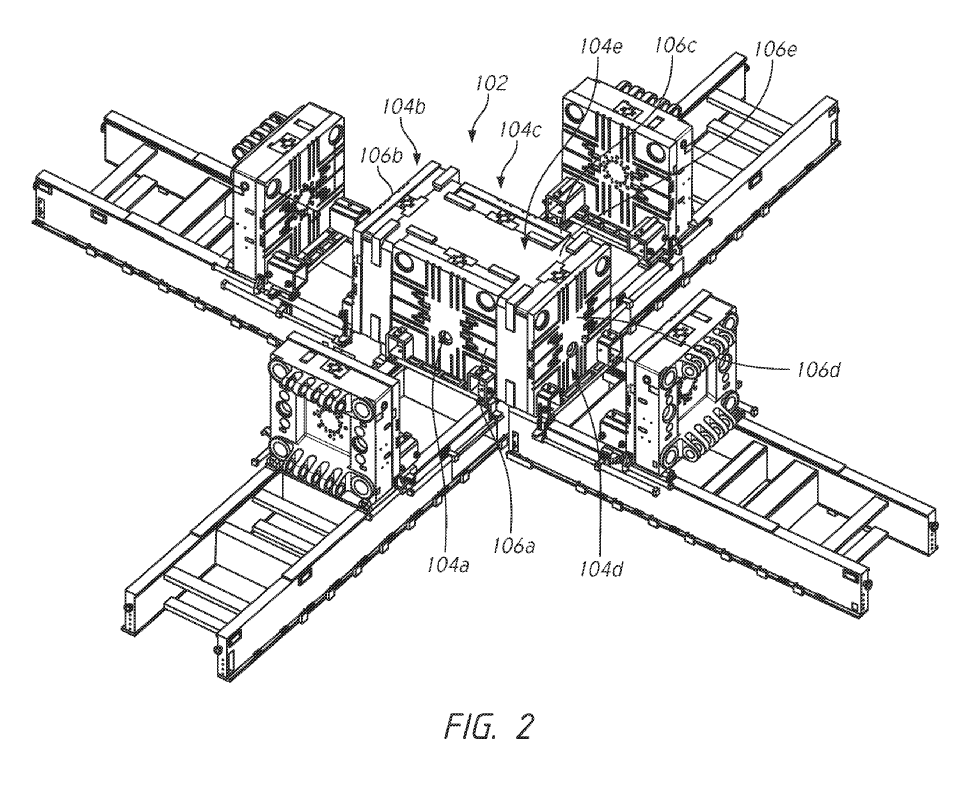

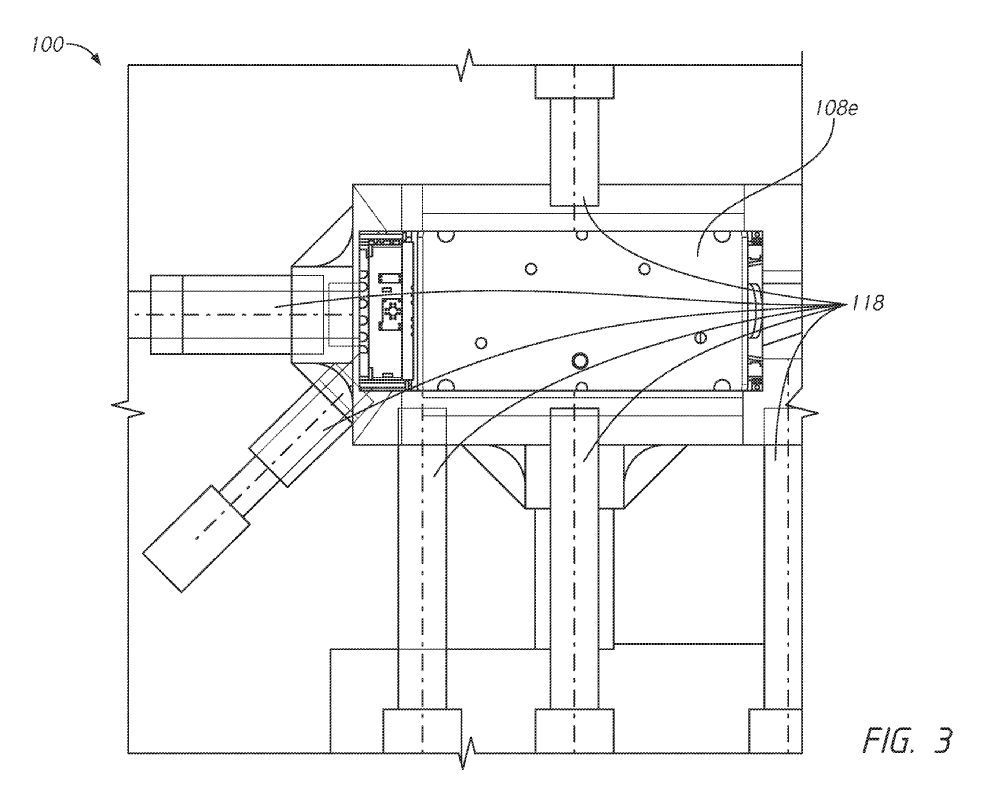

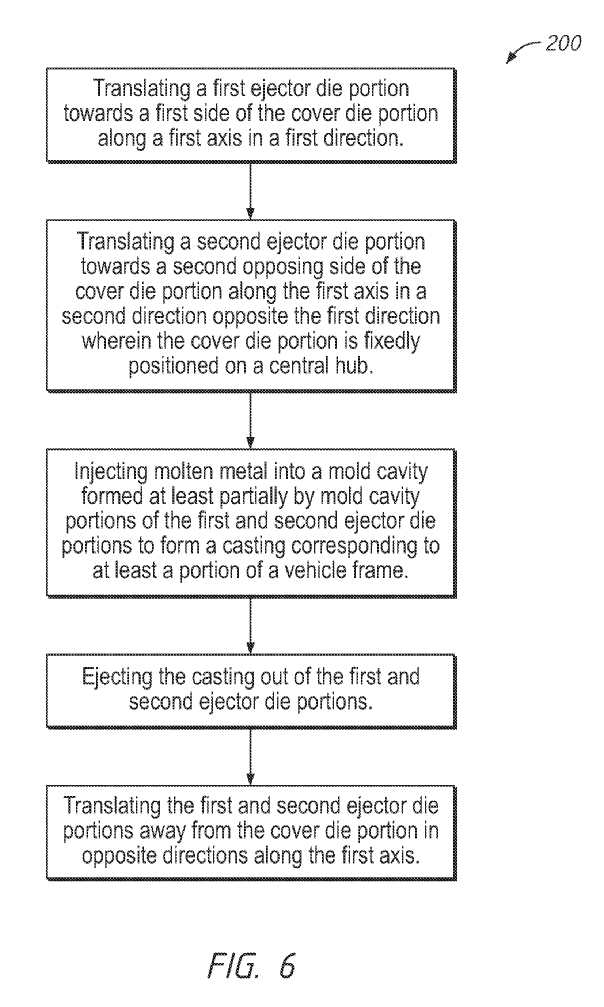

A multi-directional casting machine for casting a frame of a vehicle is described herein. The casting machine may include a central hub having a cover die portion and a plurality of ejector die portions translatable relative to the cover die portion and configured to meet at the central hub. The plurality of ejector die portions include first and second ejector die portions configured to translate along a first axis and a third ejector die portion configured to translate along a second axis extending substantially perpendicular to the first axis between closed and open positions. The first, second, and third ejector die portions are adjacent first, second, and third sides, respectively, of the cover die portion in the closed positions and spaced apart from the cover die portion in the open positions. The plurality of ejector die portions form a mold cavity corresponding to a portion of a vehicle frame.

Let’s go over this enormous Tesla unibody casting machine’s patent diagrams one by one (you can read the description under each figure, tap/click to zoom-in).

Full Patent PDF: MULTI-DIRECTIONAL UNIBODY CASTING MACHINE FOR A VEHICLE FRAME AND ASSOCIATED METHODS

Tesla Patent: Multi-Directi... by Iqtidar Ali on Scribd

No Comments